Pat Skidmore was designing tooling, setups, and

procedures starting at age 15 which resulted in a better part with

more efficient manufacturing. (He's 61 now.) In the picture below, at age 15,

he

designed some machine setups that enhanced the manufacture of this

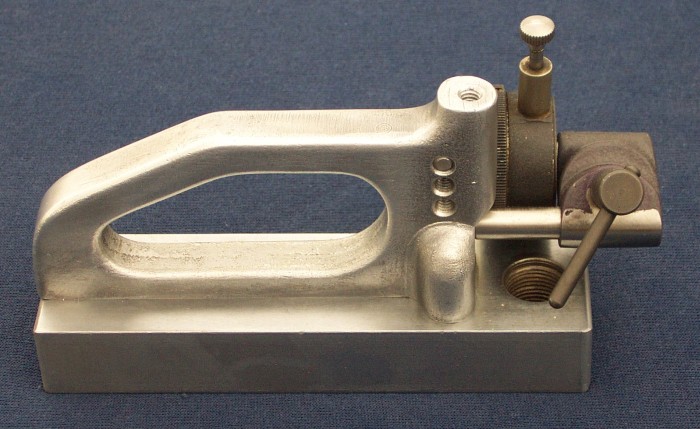

universal vice, which he also made: Pat made this parallel tool makers

clamp at age 15:

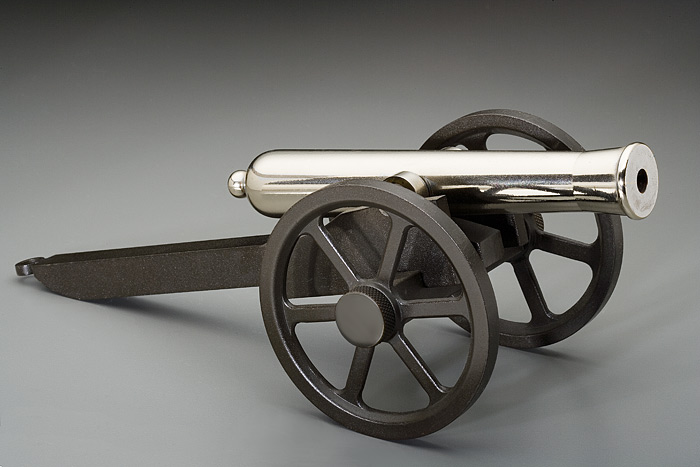

This is a small cannon Pat made at age 16:

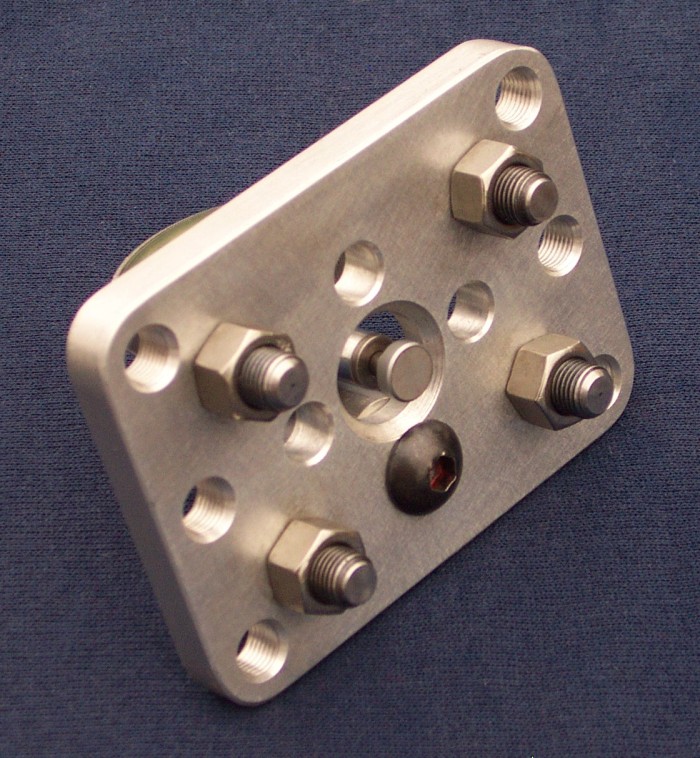

This is a trailer hitch ball Pat machined at age 16. It's made from a

single piece of type 304 stainless steel:

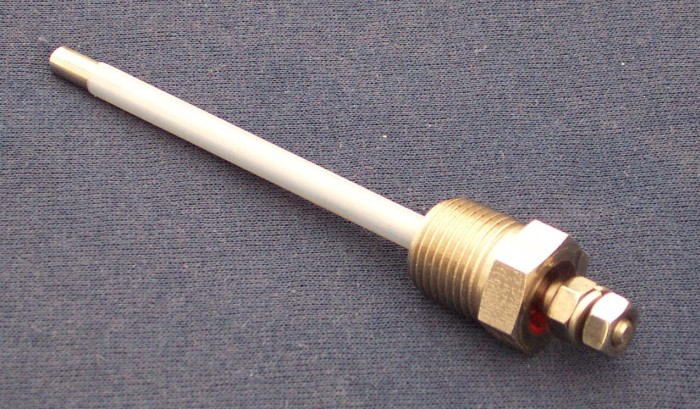

This is a vertical adjustment ring and tube Pat made to vary the

height of a Geiger counter with respect to its target. It is

used on a computer operated instrument which is used in the paint

and plastic film industry:

This is the Geiger counter housing that fits into the above vertical

adjustment tube:

These are precision scale weights that Pat made for a TVA QA lab. They're made

of type 316 stainless steel:

This is a general purpose dial indicator base Pat made to specifically set up to

gauge the parallelism of the lower platen to the cutter head of a

wood planer:

The next two pictures are a dial indicator fixture Pat made that are used to set the blades in a wood

planer cutter head.

This is a dispensing valve Pat made that metered and dispensed a radioactive

solution onto its target. A PhD in Nuclear Chemistry had previously

had valves similar to this made by other shops. None met his

metering precision criteria. Pat's did. The problem with the other

units was that the Teflon metering valve would score when rotated

from one position to another. Pat designed a method for polishing the

intersection of the main bore to the various intersecting orifices

by the use of compressed air to force an aluminum oxide slurry

through the unit to polish it. It worked:

This is a high speed spindle Pat made which is used in the electronics industry. It

carries a carbide cutting tool to trim the leads off the bottom side

of printed circuit boards after they've been wave soldered:

This is a quick change microphone test fixture Pat made for a

telephone equipment manufacturer that designed telephone equipment

for the hearing impaired:

This is a bronze lens adapter ring Pat made for an antique 8 X 10 view

camera:

This is a nylon body for a wire wound resistor made for an

electronics company:

This is a storage tank level sensing probe:

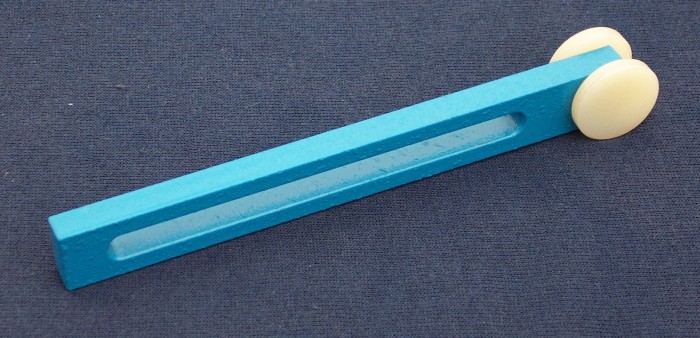

This is a powder coated aluminum link with nylon wheels.

This is a concave face stainless steel idler pulley used with a

round rubber belt. 2 bearings would be pressed into the ID:

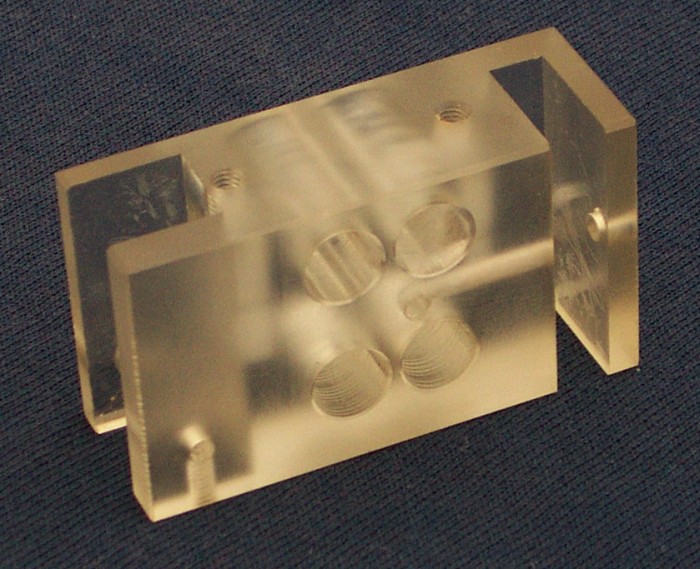

This is a highly machined acrylic block:

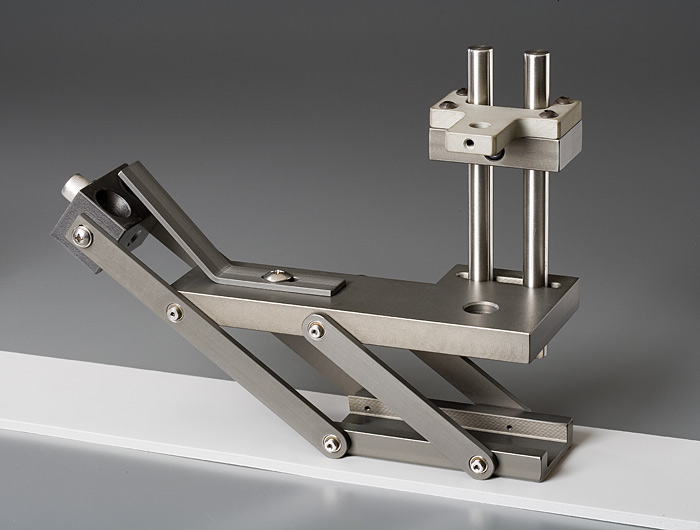

This is a sled (platen) assembly. The small bottom piece rides on urethane foam which is being slit to 2

mm thickness. It's balanced perfectly so that the force on the foam

is virtually nothing, yet enough to follow the top of the foam a

constant thickness cut. This is used by Woodbridge Foam

Manufacturing in Chattanooga. A digital indicator would be mounted

on the unit and its stylus rides on the sled. The digital indicator

provides feedback to control the thickness of the cut. You'd have to

hold this in your hand to appreciate its precision and balance: If you're a machinist that's tired of dragging your tailstock back and forth, Pat Skidmore can add an air bearing to your lathe so that you can push the tailstock back and forth with one finger. If you need any adapters made for anything, call Pat. Examples are photography, antique cars and trucks, antique machinery, motorcycle adapters, race car brackets and adapters, and anything else you can think of.

Call Pat Skidmore at 423-596-5841

|